What Thread Repair Kit or Insert is Best for Your Job?

And What is the Strength of Your Chosen Thread Repair or Insert.

You've found your Australian importer of thread repair inserts & tools - Time-Sert, Helicoil compatible wire type, Keensert, E-Z Lok, ensat, tapper and self tapping thread inserts and alternatives used for thread repair or in OEM manufacture. After about 40 years experience supplying thread inserts and tooling we'd like to say there isn't just one answer to the questions above because every job is different. You'll find below what we believe are the 4 best choices in thread repair inserts and how they work. At the bottom of this page you'll also find details of other less common and more specialised types of thread inserts. The choice is yours once you know how thread repairs and inserts work. Sparkplug, fuel injection hole and sump drain thread repair in aluminium is a common problem and you'll find the remedy at Cross Tools in our wide range of stock of the various types of thread inserts from very small to large sizes. If you've got a thread repair problem why not phone 1 800 025 500 [FreeCall] and have a chat? You can expect your order express delivered direct to you Australia-wide to most places in 24 hrs or less.

How strong will your thread repair or OEM assembly be?

Thin Wall Inserts Like Time-Sert & NuCoil

Any job repaired with any thread insert at all will be stronger than the original hole tapped straight into the parent metal. This is because when you tap an oversize thread to take the insert, you are increasing the diameter. This automatically means you have more surface area in contact with the parent and consequently more "grip". For instance in aluminium, or cast iron with a Time-Sert you probably gain 10-15% extra load bearing capacity and with a wire thread helical coil type insert maybe 20-30%. In steel, of course, a Time-Sert is the same material and a helical coil type insert is usually stainless steel. This means that you get very little extra strength from a Time-Sert but from a helical coil type insert you get maybe 10-20% extra strength due to better loading and the extra tensile strength of stainless. The pictures in the right hand column show why.

Thicker Walled Inserts Like

Big Sert and Loc-in-Sert

In aluminium or cast iron, with large diameter solid bush type inserts like Big-Serts or Loc-in-Serts, you automatically increase load bearing capacity by a substantial amount because you are making a considerably larger thread in the parent material. In steel, of course you don't gain much in strength but you do gain the benefit that if the insert strips its internal thread, you can simply screw it out and replace it generally without damage to the parent item.

The Strength Advantage of NuCoil Inserts

Hellically coiled wire thread inserts make the strongest thread connection currently known to engineers. They also increase the useful life of the

parent part because they relieve stress on the

threaded assembly. You'll see why from the diagrams below. The grey shading represents stress around the thread.

Picture at left represents a bolt straight into it's parent material without a thread insert

Notice that the grey stressed area is mainly around the top 3 threads. In fact if you measured it you would find about 50% of the load was on the first thread!

This picture represents a bolted connection with a NuCoil insert

See how the grey stressed area is nicely distributed. Stress is far more even over about 6 threads so the connection is far less likely to fail and the parent part has a longer fatigue life.

Keensert Type Key Locking Threaded Inserts - Permanent & Vibration Proof

Keyed Insert (pictured at left)

This insert locks in place by using "keys" which show in the picture protruding above the insert. Once the insert is screwed into its parent hole, the keys are knocked down into the parent and provide a positive mechanical lock. For some applications this is desirable but the keys cause slight damage to the parent thread and in some applications can lead to fluid or gas leakage e.g. in sparkplug holes. We generally prefer Loc-in-Serts featured below as a better option. The pre-applied Loctite on Loc-in-Serts does not damage the hole and, after all, Loctite is considered suitable for most critical applications these days.

Time-Serts are the same thickness as a wire thread insert and can fix a stripped thread in a hole which has very little "meat" around it. They are not quite as good at stress distribution as a helical coil type wire thread insert, but they do provide a steel thread for added strength and durability in aluminum and alloy materials. The bonus is that they are easier to fit than helical coil wire inserts because they are a solid one piece insert. Their locking system is unique. During manufacture, the last few internal threads are not cut to full depth i.e. there is excess metal left in them. This is on purpose. When you fit a Time-Sert you run a fluteless, roll forming tap through the insert and this forms the unformed metal and squeezes it out to lock the insert in.

Familiar with Time-Serts?

Click here for product list

<Roll Pin

Big-Sert

Thick wall version of Time-Sert for second repair or badly damaged holes.

Where you have a Time-Sert or helical coil type insert that has stripped or you've got a badly damaged hole, you need a thicker walled insert and Big-Sert is the answer. Big-Serts require special tooling and as with a Time-Sert, excess metal is left in the last few threads of the insert. A fluteless tap is used to fit the Big-Sert. As this tap is forming the last few threads inside the insert it also squeezes a small roll pin out into the parent thread to lock the Big-Sert in.

Familiar with Big-Serts?

Click here for product list

NuCoil

Helicoil compatible wire thread inserts for recoiling stripped threads and for OEM uses. Very thin section (same as Time-Sert) - suits a first time repair.

Wire thread inserts are the strongest type of threaded connection. For this reason threads in critical applic-ations such as inside aircraft turbines and nuclear reactors are fitted with wire thread inserts from new. That's right, critical threads where breakage would endager life are not just tapped straight into the parent metal. The reason is explained in the diagrams in the "How strong will your thread repair be" section below. We do not recommend wire thread inserts for sump and drain hole or sparkplug hole repairs and they are harder to fit than Time-Serts in difficult locations.

Because the wire in these inserts can flex slightly, the insert acts like a shock absorber and distributes the the load better between parts.

Familiar with Helicoils ?

Click here for product list

Loc-in-Sert

Thick wall insert for repair where thinwall inserts have failed. Also used in dies for plastic moulding and metal stamping.

Loc-in-Serts are thick wall threaded bushes and are good for a repair if a helical coil or Time-Sert insert has failed. They are also used in plastic moulding and metal stamping dies and machinery. The advantage of Loc-in Serts is that they use standard size taps and have ordinary threads on the outside. So special tools are not needed and setup cost is low. When used as hold down threads in plastic and stamping dies they become a replaceable threaded bush i.e. when the thread wears they are relatively easy to remove and do not damage the parent thread. You simply screw a new Loc-in-sert in and you have a brand new thread! Pre-applied Loctite on the outside of the insert self activates as you screw a Loc-in-Sert in and automatically stops it coming out.

Familiar with LocinSerts?

Click here for product list

How to measure a thread . . .

What do you need to know for starters?

To illustrate how to measure a thread let's use the most familiar member of the screw thread family - a bolt. If you need to describe any thread, including thread repair inserts, you need to know accurately the "pitch" and the "diameter". You should always try to have the male thread available to measure e.g. a bolt or stud rather than try to measure an internal thread. Measuring internal threads accurately is far more difficult and open to errors.

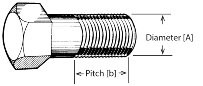

The elements needed to measure a thread are illustrated on the bolt pictured below:

Diameter [A]: This needs to be measured with a precision caliper or micrometer to be sure what thread you have.

An example of how a METRIC THREAD is described is: either 10mm x1.5 or M10x1.5 (both terms mean the same thread) which is 10mm diameter and 1.5mm thread "Pitch" as pictured [b] above.

This "pitch" 1.5mm is the distance between

each hill or peak on the thread as pictured

IMPERIAL or "INCH" threads are described differently for example: 3/8"-16 UNC or 3/8"-16 BSW

3/8" is the diameter and 16 is the "Pitch" [b] (as per picture above). But in the "inch" system pitch is said to be so many threads to every inch of thread length. (In the example above this is 16 threads per inch). "Threads per inch" is also abbreviated to its initials " tpi" for short. So, the "inch" system describes pitch as the number of threads over a one inch length and not as the distance between the peaks of a thread like the metric system.

An INCH thread will usually be followed by some initials like the example above. These initials describe the type and the engineering standard for the thread. For the above example UNC stands for "Unified National Coarse" and BSW stands for "British Standard Whitworth". To an engineer, this classifies and defines the type of thread.

Self Tapping Thread Inserts

Self Tapping Inserts (2 pictures at left)

These inserts cut their own thread using either a sharp sided slot or hole. Both types are pictured. The external threads are often shallower than a tapped hole and we consider them not the best insert to use for repairs. One reason is it's easier to misalign this type of insert. Their main application is in OEM either in softer metals or plastic where mass tooling can be set up to manufacture.

Fast delivery Australia-wide direct

from your importer & trade supplier

Phone FreeCall 1800 025 500

Back

to

Top